Headquarters

CANADA

API 6D: 6D-1342 API Spec Q1:Q1-4181 ISO 9001:2015: 0052985-01

CHINA

API 6D: 6D1822- API 6A: 6A-2250 API Spec Q1: Q1-3641 ISO 9001:2015: ISO3983-

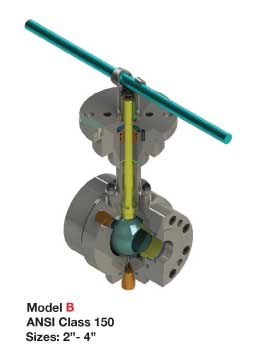

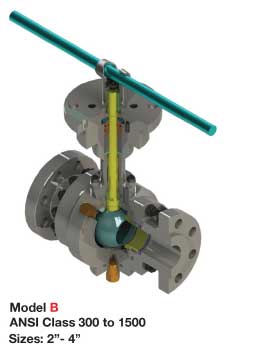

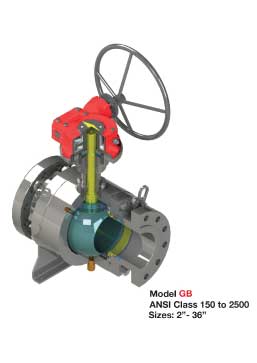

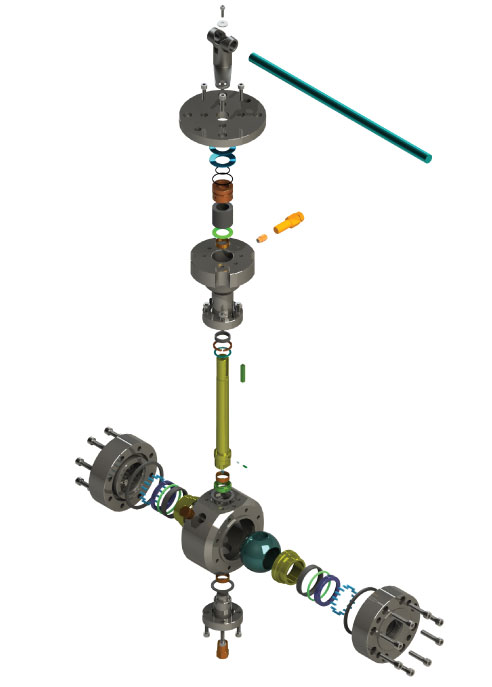

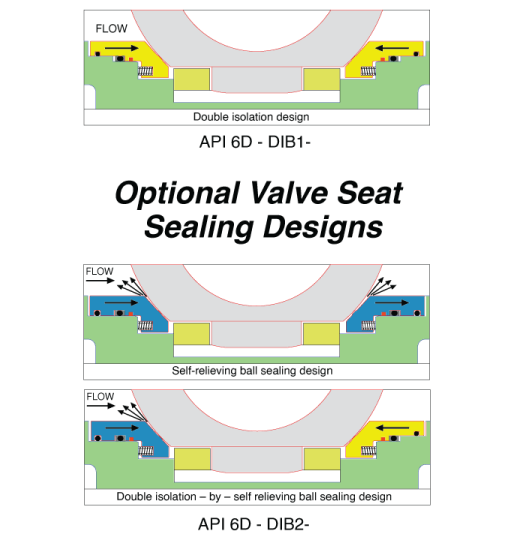

Guide Valve Limited, established in 1980 with it’s headquarters In ontario, Canada , specializes in the manufacturing of valves. We are manufacturer of the trademark brands such as , GVS®, VCI®, Lowe & GVS®-Malema. Our products are based on the most advanced technologies and are used in all sectors from petrochemical refining, process to transportation and distribution of the end product. GVS valves are designed , manufactured & tested according to API 6D, API 6A and CSA Z245.15 and available to 608 . The GVL organization gas achieved SIL 3 Certification by an independent 3rd party agency . Our standard product design of Series B & GB are of the trunnion mounted, bolted body forged type ball valves.

ANSI Class 150 Wafer Body

ANSI Class 300 To 1500

ANSI Class 150 To 2500

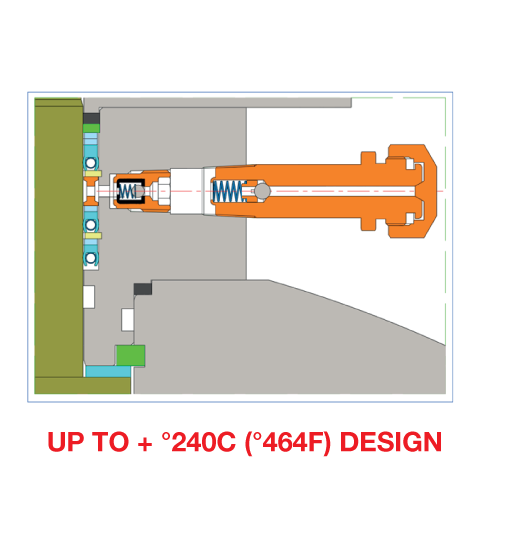

UP TO °240+C (°464F)

UP TO °240+C (°464F)

UP TO °240+C (°464F)

UP TO °240+C (°464F)

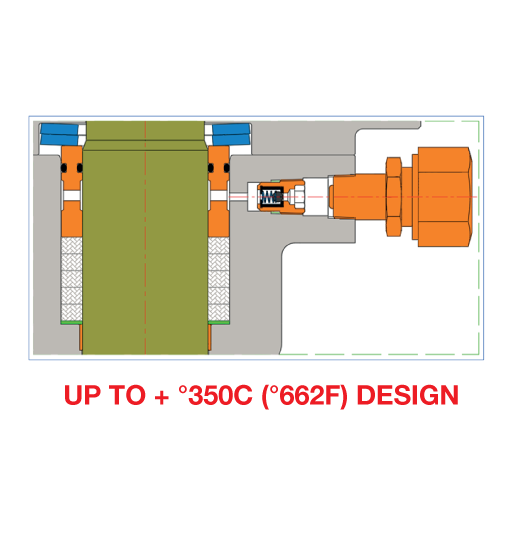

UP TO °350+C (°662F)

UP TO °350+C (°662F)

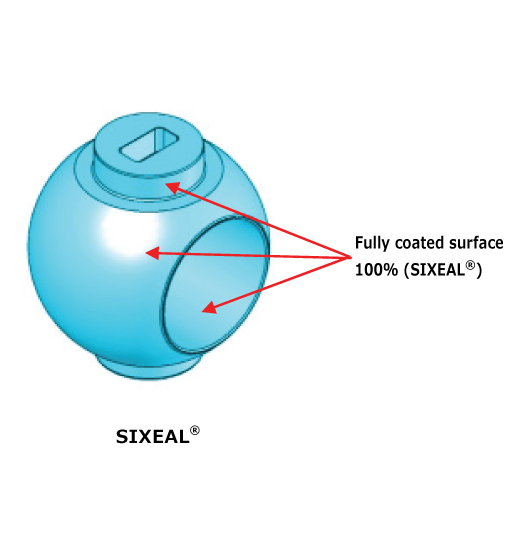

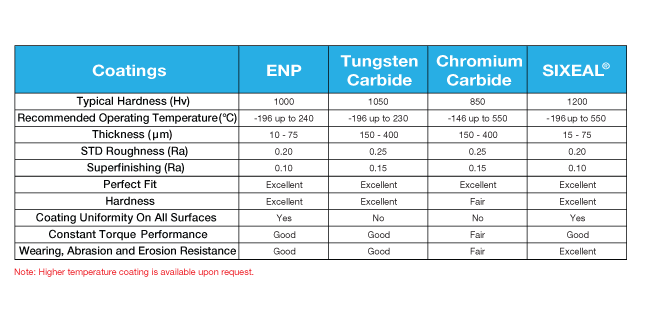

SIXEAL® is recommended onto our GVS® Trunnion Mounted Metal to Metal Ball Valves where high resistance to abrasion, corrosion and wearing are required. For example, in slurry and sandy environments SIXEAL® is a viable alternative to HVOF coating.

Micro-particles of silicon carbide are added into the ENP bath to obtain a final plating in which incorporated sub-particles are evenly distributed all over the treated surfaces. The result is a homogeneous hard-faced element strongly incorporated in a nickel matrix, matching the hardness properties of silicon and the chemical resistance of ENP. This uniquely developed process is based on electroless nickel plating procedure. SIXEAL® coating thickness is maintained equally all over the coated surfaces, “complete ball”. This process eliminates any further grinding or machining of the ball’s outer surface.

ISO 15848-1

ENDURANCE CLASS CO3 TIGHTNESS CLASS AM

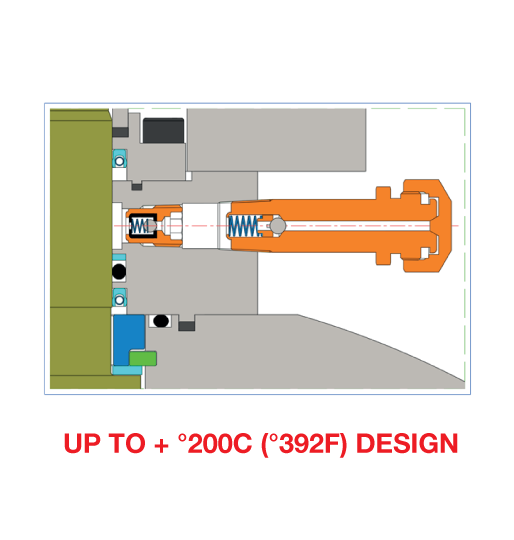

+200°C

API STANDARD 641

+240°C

API STANDARD 641

ISO 15848-1

ENDURANCE CLASS CO2 TIGHTNESS CLASS CH

+350°C

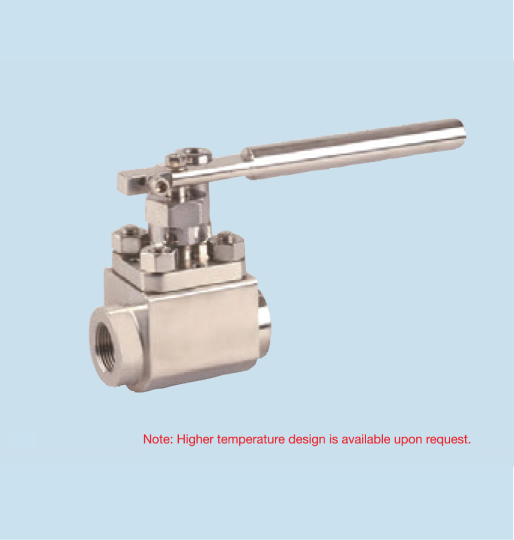

Note: Higher temperature design is available upon request

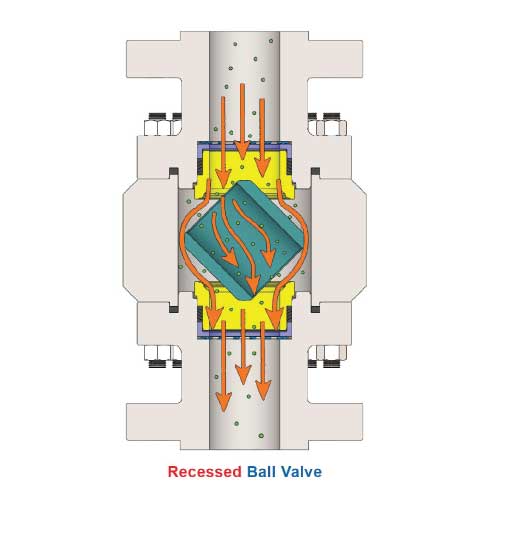

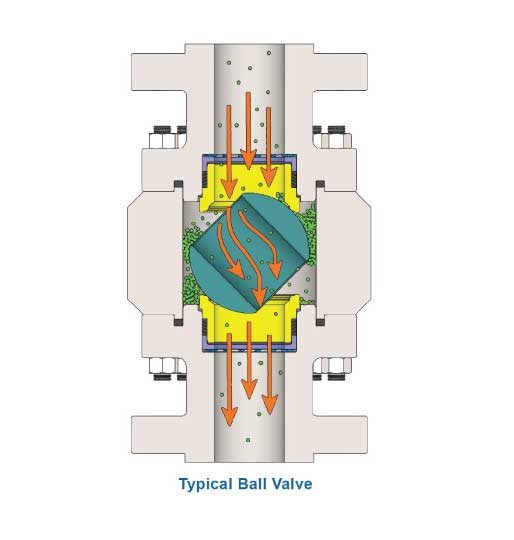

When the valve is in closed position, the upstream face which is exposed to the corrosive gases and fluids tend to pit the area go the ball bounded by the valve seat, causing the critical smooth surface finish to become rough . Because the ball is fitted with zero clearance to the seats, any roughness or protrusions caused by corrosive or erosive attack will damage the valve seats during the rotation of the ball , once the seats are damaged , effective sealing is lost . Continued cycling increases the seat damage.

Valves that handle fluids and gases that tend to deposit crustations, or leave residue on the inner valve surfaces, will become hard to operate. With the ball valve in the closed position for lengthy time periods, the build-up of deposits adheres to the ball face within the seat boundaries, causing interference with the valve seats during attempts to cycle the valve. Only a few thousandths deposit on the ball face will increase turning torque and damage seats. Excessive crustations or residue on the ball face will make the valve inoperative.

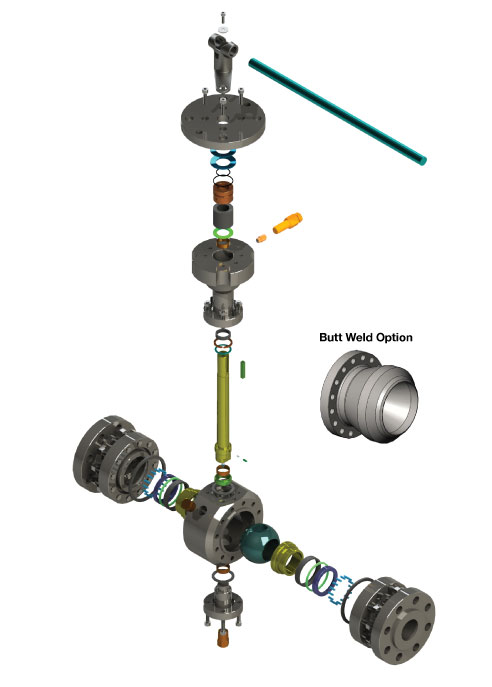

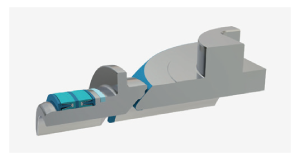

Metal to Metal seated , 3 pieces bolted body ball valve in 1/2" to 4", in NPT,SW,BW & RF flanges with temperature range up to + 350ºC (+662ºF).

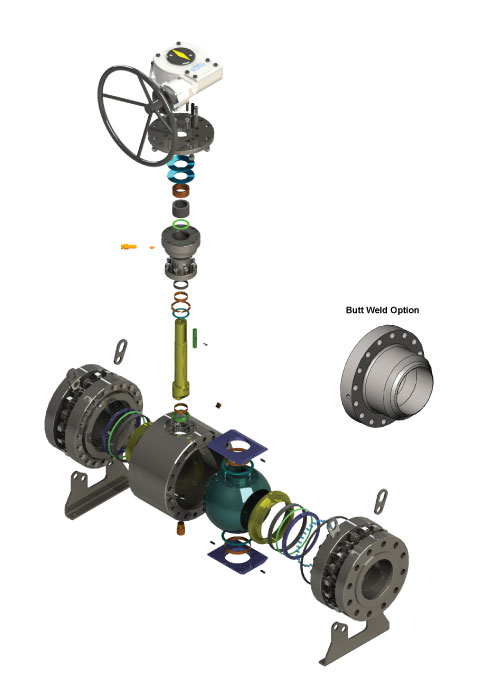

Metal to Metal seated ball valve in 1/2 to 12" of ANSI Class 150 to 2500,RF Flanged, Fill Ported, Bolted Body style with Temperature to +350ºC (+662ºF).

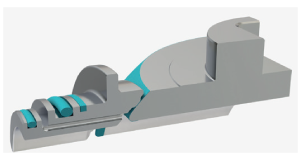

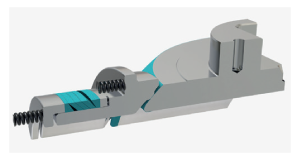

The Lowe valve design offers an unique quarter turn rotary wedge action, metal to metal seated valve which provides bubble tight shut-off performance.Features such as non-lubricated, low torque, quarter turn operation, multiple wear compensation adjustements, bach seatin, and economocal quarter turn actuator compatibility are an integral part of this valve. the lowe valve is proven high pressure, high temperature valve to +649ºC (+1,200ºF). Availble in carbon Steel and stainless Steel construction with Threaded,Socket-weld,butt-weld or Flanged Ends to ANSI Classs 900 And to sizes of 2"

Contact US

905-761-7877